Multi-Gang Switch Customization Becomes New Growth Point for Manufacturers

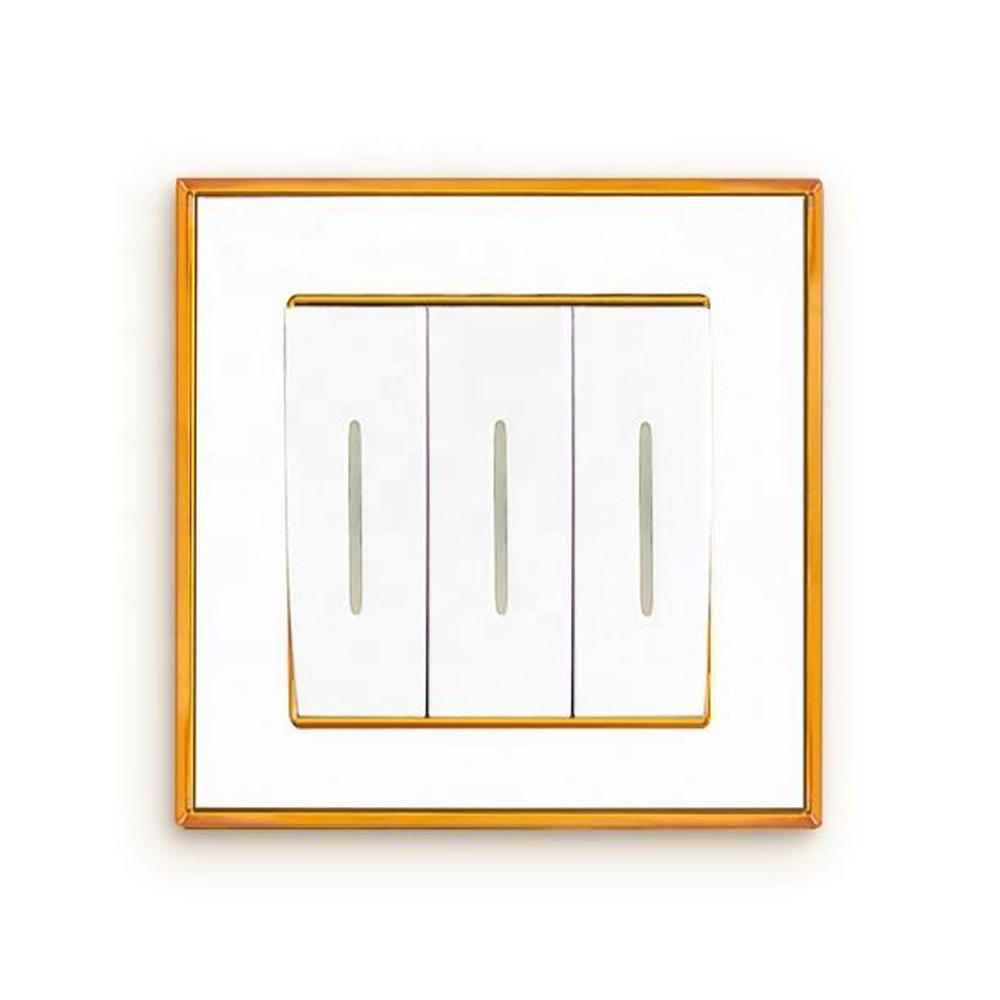

Multi-gang switch customization has emerged as a key growth area for electrical switch manufacturers. Clients increasingly seek switch panels that can combine multiple functions, support various electrical configurations, and fit different aesthetic requirements. Manufacturers have responded by offering modular designs that allow clients to select the number of gang units, materials, colors, and finishes according to project needs.

Customization not only meets the functional requirements of residential, commercial, and industrial installations but also allows manufacturers to differentiate their products in competitive markets. Multi-gang switch panels can be tailored to integrate lighting controls, USB charging ports, and smart home features in one unit. This flexibility supports architects, contractors, and homeowners in designing electrical systems that align with spatial layouts and usage patterns.

Modular customization enables manufacturers to manage production efficiently, as standardized components can be assembled into varied configurations. This approach reduces lead times while meeting client expectations for tailored solutions. Factories are exploring options such as interchangeable faceplates, customizable labeling, and modular electrical interfaces, further expanding the appeal of multi-gang switch products. The growing demand for personalized electrical solutions positions customization as a strategic growth driver for the industry.

Factories Optimize Gang Switch Designs to Improve Durability and Safety

Durability and safety have become central considerations for gang switch manufacturers. Factories are enhancing materials, production processes, and design protocols to ensure switches perform reliably under various operating conditions. High-quality plastics, flame-retardant coatings, and reinforced contact components are increasingly standard in modern multi-gang switches.

Manufacturers conduct rigorous testing for mechanical strength, thermal resistance, and electrical insulation to prevent failures and ensure long-term performance. Safety features, such as overload protection, fire-resistant housings, and child-safe mechanisms, are being incorporated into designs to reduce risks in residential and commercial settings.

Factories are adopting advanced assembly techniques to enhance consistency across production batches. Automated quality inspections, real-time monitoring systems, and standard operating procedures help identify defects early, maintaining high reliability. By focusing on durability and safety, manufacturers strengthen brand reputation, build customer trust, and support the broader adoption of modern electrical systems across markets.

Gang Switch Manufacturers Promote Multi-Protocol Smart Integration

The rise of smart homes and connected infrastructure has created opportunities for gang switch manufacturers to incorporate multi-protocol smart integration. Modern switches now often support wireless control, including Wi-Fi, Zigbee, and Bluetooth communication protocols. This allows end-users to control lighting, appliances, and other systems remotely through mobile devices or centralized automation platforms.

Factories are designing switches with embedded modules that can connect to smart hubs, voice assistants, and energy management systems. Multi-protocol compatibility ensures interoperability across different devices and ecosystems, increasing product appeal to tech-savvy consumers. Manufacturers also focus on maintaining robust security standards in smart switches, including encrypted communication and firmware update mechanisms.

Integration of multi-protocol smart capabilities provides flexibility in residential, commercial, and industrial installations. Users can schedule operations, monitor energy usage, and adjust settings based on real-time data. Incorporating smart integration allows gang switch manufacturers to expand product offerings into high-value markets and align solutions to evolving technological trends.

Gang Switch Manufacturers Increase Production Automation to Handle Orders

To meet increasing demand and maintain consistent quality, gang switch manufacturers are investing in production automation. Automated assembly lines, precision molding machines, and robotic handling systems have been introduced in many factories to reduce manual labor requirements and minimize production errors.

Automation enables manufacturers to produce large volumes of standard switches and customized multi-gang units simultaneously, maintaining efficiency without compromising quality. Real-time monitoring systems allow operators to track production performance, identify bottlenecks, and adjust operations as needed. Predictive maintenance programs help prevent equipment downtime, ensuring continuous output.

Automated testing stations verify electrical performance, contact reliability, and mechanical durability at scale. Integrating automation into production allows factories to manage larger orders, respond rapidly to market fluctuations, and meet the expectations of international clients. This approach strengthens operational resilience and supports sustainable growth in global markets.

Consumer Preferences Drive Factories to Develop Touch and Smart Gang Switches

Consumer demand is shaping the evolution of gang switch products. Modern users increasingly prefer touch-sensitive interfaces, illuminated panels, and smart functionalities that provide convenience and aesthetic appeal. Manufacturers are responding by incorporating capacitive touch controls, soft-glow indicators, and modular connectivity options into multi-gang switches.

Touch and smart gang switches allow for advanced control, including dimming, scene setting, and remote operation via mobile apps. Energy management features, such as monitoring consumption and integrating with home automation systems, have become standard expectations for many consumers.

Factories are also focusing on design elements that complement interior spaces, including minimalistic faceplates, customizable finishes, and ergonomic layouts. By aligning product design with consumer preferences, manufacturers increase market acceptance and create opportunities for cross-market adoption in residential and commercial projects. The trend toward touch and smart switches reflects the broader shift toward integrated, intelligent living solutions.

Asian Gang Switch Factories Maintain Global Production Hub Status

Asian factories remain central to the global production of gang switches. The region’s manufacturing capabilities, skilled workforce, and access to raw materials provide a competitive advantage in meeting international demand. Factories in countries such as China, India, and South Korea supply standard and customized multi-gang switches to markets across Europe, North America, and the Middle East.

These factories emphasize scalability, quality control, and adherence to international certifications, ensuring their products meet global standards. Export-oriented production models allow manufacturers to respond to orders of varying sizes while maintaining consistent delivery timelines.

Regional factories are investing in advanced technologies, including automated production lines, smart testing systems, and modular assembly solutions. This enables them to supply high-quality gang switch products at competitive prices while supporting innovation in design, smart integration, and safety compliance. Asian production hubs continue to play a pivotal role in supplying global electrical switch markets and supporting the adoption of modern electrical infrastructure worldwide.

Wenzhou Lipoer Electrics Co., Ltd. exemplifies the strength of Asian gang switch factories in the global electrical components market. Established in 2010 and located in the Wenzhou Economic and Technological Development Zone in Zhejiang Province, Lipoer operates a modern production facility covering over 4,000 m² and producing up to 1,000,000 electrical switches per month. The company employs skilled professionals across departments including R&D, material control, tooling, automated assembly, and quality assurance, ensuring consistent manufacturing performance and product delivery.

Lipoer’s product range includes multi‑gang switches, wall plates, and PC/PP switch models available in a variety of configurations suitable for international markets. Advanced production equipment and strict quality control protocols support the company’s ability to meet diverse standards and customer requirements across Southeast Asia, the Middle East, Europe, South America, and Africa.

عربى

عربى