Electrical Switch Manufacturers Expand Production Capacity to Support Industry Growth

Electrical switch manufacturers are actively increasing production capacity to meet growing demand across multiple sectors. Rising construction activity, industrial automation projects, and residential infrastructure development have contributed to the need for reliable electrical switching solutions. Manufacturers are responding by upgrading facilities, modernizing machinery, and streamlining production lines to ensure timely delivery of quality components.

The expansion of production capacity enables manufacturers to serve a diverse range of clients, including industrial equipment suppliers, building contractors, and commercial project developers. Enhanced production capabilities also support shorter lead times, allowing manufacturers to adapt to fluctuating market requirements efficiently. Investment in advanced equipment such as automated assembly lines, precision molding machines, and quality inspection systems has improved operational efficiency and reduced production bottlenecks.

Manufacturers are implementing modular production strategies that allow for flexible adjustments to product volumes. This approach ensures that both high-demand standard switch units and specialized configurations can be manufactured concurrently without compromising quality. Manufacturers are integrating real-time production monitoring systems and predictive maintenance programs, which help identify potential issues early and reduce downtime. Continuous process optimization and workforce training further enhance productivity, ensuring consistent product quality across all production batches.

Electrical Switch Manufacturers Address Supply Chain and Logistics Challenges

Supply chain and logistics management remain critical considerations for electrical switch manufacturers. Raw materials, components, and packaging materials must be procured reliably to maintain consistent production output. Recent fluctuations in material availability, transportation delays, and regional logistical disruptions have prompted manufacturers to adopt proactive strategies to minimize operational impact.

Manufacturers are diversifying supplier networks to reduce dependence on single sources for metals, plastics, and electronic components. Long-term procurement agreements, regional sourcing, and strategic inventory management help mitigate the risks of supply shortages. Advanced forecasting tools and production planning systems allow companies to anticipate potential disruptions and adjust schedules accordingly.

Logistics optimization has also become a focus. Manufacturers coordinate with carriers, optimize shipping routes, and implement warehousing strategies that enable faster distribution to domestic and international markets. Integration of digital tracking and monitoring systems ensures visibility across the supply chain, improving responsiveness and reducing delays.

Manufacturers are increasingly collaborating with logistics partners to implement just-in-time delivery models, minimizing storage costs while maintaining sufficient buffer stock. Addressing supply chain and logistics challenges systematically allows electrical switch manufacturers to maintain stable operations, support growing demand, and enhance customer confidence in product reliability.

Electrical Switch Manufacturers Promote Product Diversification to Attract New Markets

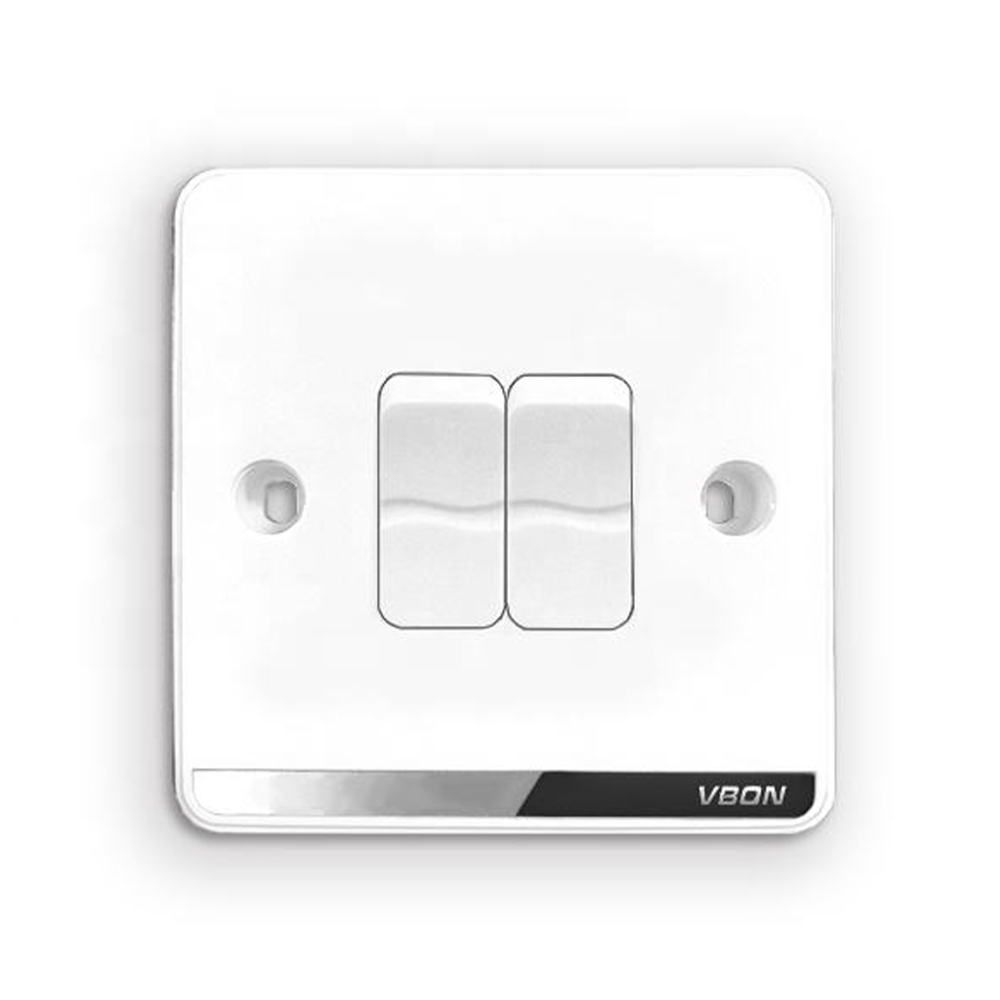

Product diversification is a strategic approach adopted by electrical switch manufacturers to attract new market segments and meet evolving customer expectations. Beyond traditional mechanical switches, manufacturers are developing modular switch units, integrated USB outlets, smart home compatible switches, and multi-function panels.

Diversification supports entry into specialized sectors such as industrial automation, intelligent building management, and energy-efficient residential systems. Modular designs allow clients to select configurations that meet specific electrical, aesthetic, or functional requirements, providing a higher level of customization.

Manufacturers also invest in research and development to explore materials, coatings, and functional enhancements that improve product longevity, safety, and user experience. This includes designing switches that are more durable, chemically resistant, and compatible with varied voltage standards across different regions.

Marketing strategies emphasize the expanded product portfolio to demonstrate versatility and capability to potential clients. Offering a wide range of solutions allows electrical switch manufacturers to target both traditional construction markets and emerging sectors, ensuring continued relevance and growth in a competitive landscape.

Electrical Switch Manufacturers Emphasize Safety Standards and Compliance

Safety is a central concern in the electrical switch industry. Manufacturers focus on compliance with regulatory standards, quality control protocols, and industry best practices to ensure products operate reliably and safely in residential, commercial, and industrial environments.

Switch components are tested for electrical insulation, contact stability, thermal resistance, and mechanical durability. Child safety features, fire-resistant materials, and anti-overload mechanisms are increasingly integrated into modern switch designs. These measures reduce the risk of accidents and support end-user confidence in product reliability.

Manufacturers also maintain comprehensive quality assurance processes, including routine inspections, performance testing, and certification verification. Advanced testing techniques simulate real-world usage conditions, ensuring that switches perform reliably under repeated operation, environmental stress, and varying electrical loads.

Safety compliance extends beyond product design to include installation guidance, packaging labels, and user instructions. Clear documentation assists electricians, contractors, and end-users in proper installation and safe operation. Emphasizing safety standards and regulatory adherence allows electrical switch manufacturers to reinforce brand reputation and foster trust in domestic and international markets.

Ongoing employee training and adherence to updated safety protocols ensure that production staff are equipped to handle potential hazards effectively. Regular audits and continuous improvement programs help identify areas for enhancement, further strengthening the reliability of switch products. This holistic approach demonstrates a manufacturer’s commitment to long-term product quality and user protection, meeting both regulatory requirements and customer expectations worldwide.

Electrical Switch Manufacturers Expand Customized Product Lines to Meet Market Segmentation

Market segmentation requires electrical switch manufacturers to offer customized products that cater to specific client needs. Customized switch lines allow manufacturers to provide different designs, finishes, functionalities, and electrical configurations suitable for residential, commercial, or industrial applications.

Customization can include variations such as rocker switches, toggle switches, modular panels, and integrated smart features. Clients may request particular colors, surface textures, labeling, or mounting options to align with architectural and design requirements. These options enhance customer satisfaction and support branding differentiation in construction and infrastructure projects.

Manufacturers also offer flexible production capabilities to accommodate small-batch custom orders alongside large-scale standard products. Production lines are configured to manage varying material requirements, assembly processes, and quality control checks to ensure consistency across different product variations.

Data from client projects indicate growing interest in tailored electrical solutions that reflect regional standards, aesthetic preferences, and technological compatibility. Manufacturers responding to this trend strengthen their market position and increase opportunities for international expansion. Customization not only addresses client-specific demands but also helps manufacturers differentiate themselves in a competitive global market.

Conclusion

Electrical switch manufacturers are navigating a dynamic and evolving industry through strategic expansion, operational resilience, and product innovation. Increasing production capacity enables manufacturers to meet growing global demand while maintaining efficiency and quality. At the same time, proactive management of supply chain and logistics challenges ensures stable operations despite fluctuations in materials, transportation, and market conditions. Diversifying product portfolios allows manufacturers to enter new markets and respond to shifting consumer and industrial needs, offering solutions that range from standard switches to integrated, smart, and modular designs.

عربى

عربى