Every evening you flick the same switch to turn on the living-room lights, but when did you last ask whether that humble wall switch socket is actually safe? Across the globe, electrical accessories still cause thousands of residential fires each year, and many originate at the point where the building’s fixed wiring meets the device you touch every day. Understanding the risks—and the simple steps that eliminate them—can mean the difference between a cozy night in and a call to the fire department.

To begin with, know your enemy. The biggest hazards inside a wall switch socket are poor connections, sub-standard materials, and age-related fatigue. A loose terminal screw can arc, carbonize surrounding plastic, and reach ignition temperatures in minutes. Cheap knock-off sockets often use brass-plated iron instead of solid copper contacts; the plating erodes, resistance rises, and heat follows. Meanwhile, decades-old bakelite or early thermoplastics become brittle, allowing live parts to shift and short-circuit against the metal yoke.

Start your safety audit by listening. A properly installed wall switch socket should operate in complete silence. Any crackling, popping, or buzzing indicates arcing inside. Next, perform a fingertip test: after the switch has been on for fifteen minutes, the toggle or rocker should feel no warmer than body temperature. Anything hotter suggests either an overloaded circuit or internal resistance. Finally, use your nose; the acrid smell of overheated PVC is unmistakable and means immediate de-energizing is required.

Visual inspection is equally revealing. Remove the faceplate (power off at the breaker, never just the switch) and look for discoloration, melted plastic, or green corrosion on the terminals. If the back-stab push-in connectors were used, consider rewiring to the side screws, which provide far better clamping force and lower resistance. While you are there, check that the ground conductor is securely bonded; many older homes skipped the ground entirely, leaving metal parts energized during a fault.

Standards matter. In North America, insist on wall switch sockets bearing UL or ETL marks; in Europe, look for CE and VDE logos; in Australia and New Zealand, the Regulatory Compliance Mark (RCM) is mandatory. These symbols certify that samples have passed glow-wire flammability tests, terminal torque tests, and endurance cycles equivalent to twenty years of daily use. Beware of online marketplaces where listings claim “UL certified” yet ship units with no markings at all—counterfeits are rife.

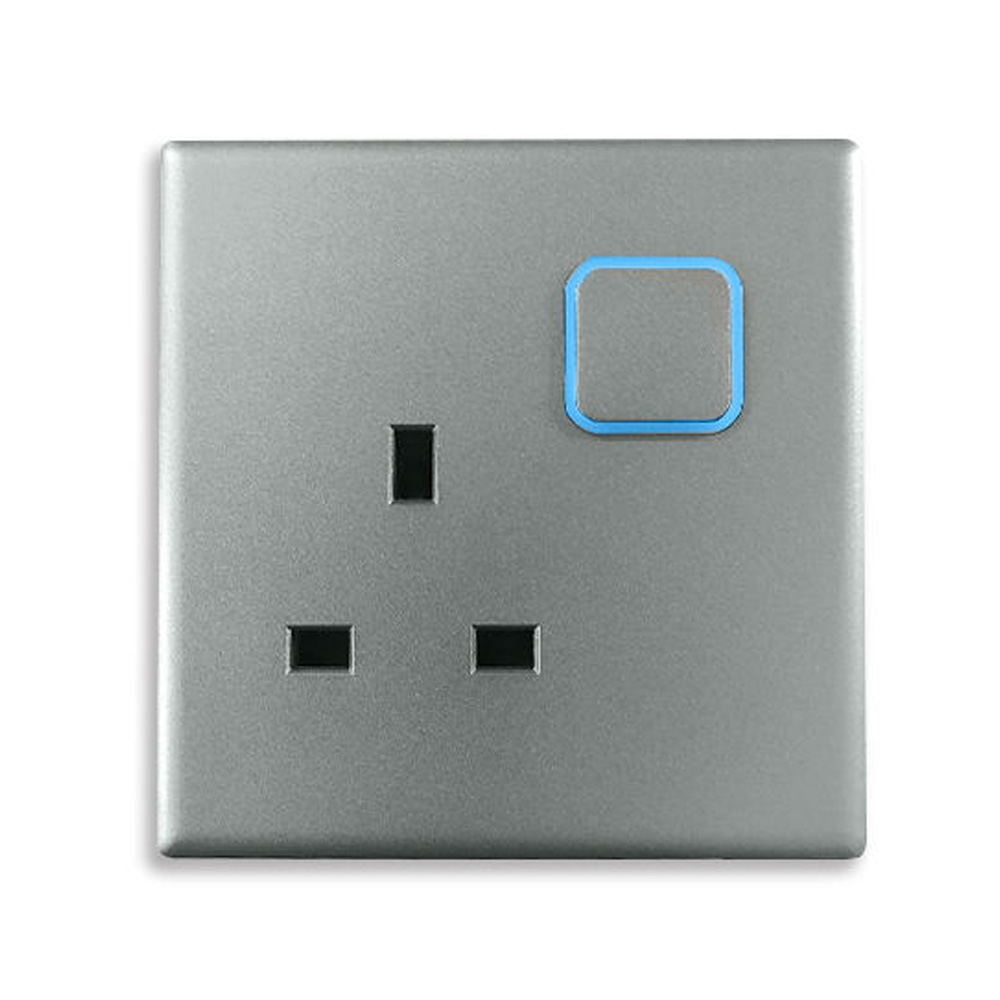

Technology offers extra layers of protection. Arc-fault circuit interrupter (AFCI) breakers detect the signature waveform of dangerous arcing and shut off power before ignition occurs. Ground-fault circuit interrupter (GFCI) protection is mandatory in wet locations and prevents lethal shocks if a socket’s internals are compromised. Smart wall switch sockets with built-in temperature sensors can push alerts to your phone the moment internal heat rises above a safe threshold, giving you time to act rather than react.

Installation discipline is the final safeguard. Use the correct torque specified on the device—too low and the wire loosens under thermal cycling; too high and the screw threads strip. Strip conductors to the length shown in the instructions; exposed copper outside the clamp becomes a spark gap. Box-fill calculations matter as well. Cramming extra wires around a bulky smart switch elevates temperature and accelerates insulation breakdown. When in doubt, install a deeper box or use pigtails to reduce congestion.

عربى

عربى